Ballistic Resistant Steel Windows UL 752 / NIJ III BR & BLAST

Ballistic Resistant Steel Windows

UL 752 / NIJ III BR & BLAST

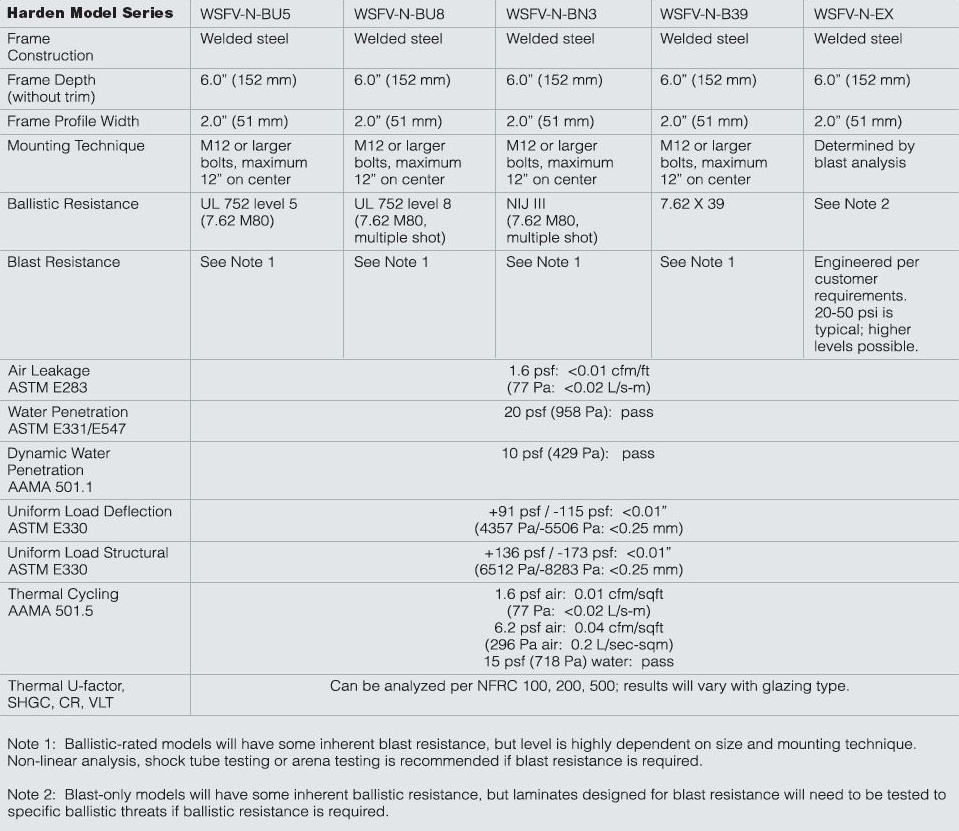

Tested to withstand rifle-level ballistic threats for UL 752 levels 5 and 8, NIJ III and 7.62 x 39 rounds. Available as non-operable systems in various shapes with optional deal tray and engineered blast load ratings up to 40 psi / 300 psi-ms and beyond.

Design Overview

ANTI-TERRORISM LEVEL SECURITY where the threat of rifle-level ballistic and high level blast attacks exist

MINIMAL SIGHT LINES where a limited view of the window’s framing system is an important component of the overall building design

ARCHITECTURAL DESIGN the ability to form numerous shapes and configurations facilitates integration with other architectural elements

DESIGN FLEXIBILITY where architectural or security objectives require the use of large or ganged window systems

DURABILITY galvanized, structural steel provides maximum durability and low maintenance

Harden Steel Ballistic Resistant Windows offer an ideal solution where the call for high ballistics resistance is combined with requirements for minimalistic or uniquely shaped frames. The WSFV-N-B series are tested to meet multiple firearm threat levels including UL 752 (Levels 5 & 8), NIJ III and 7.62 x 39 rounds. The WSFV-N-EX is engineered to resist blast loads up to 40 psi / 300 psi-ms and beyond. Custom designs are available to meet combined blast and ballistic threats.

- Government

- Military

- Oil & Gas

- Critical Infrastructure

- Commercial

- Full window system, factory glazed, with shipping bolts to retain stops and glazing to frame

- Structural steel frame with welded corners

- Laminated glazing to meet the applicable threat

- Removable glazing stops

- Ballistic trim to protect construction shim gap (on ballistic-rated units)

- Pre-drilled and tapped sub-frame in one of three styles

- embed plate with studs for newly poured concrete walls

- tubing with chemical or mechanical anchors for existing masonry walls

- tubing for welding to steel walls

Standard Finish – Frame and Glazing Stops

- Hot-dip galvanized per ASTM A123

Standard Finish – Optional Interior/Exterior Trim

- Manufacturer’s standard finish coat (Contact Harden for color chart)

Window System

- Transaction tray with interior lid and stainless steel interior/exterior trim

- Transaction drawer with interior lid and stainless steel interior/exterior trim

- Snap-on interior window trim

- Exterior window trim

- Blast-rated glazing and anchorage systems (user-defined blast loads)

Glazing

- Low-e hardcoats

- Films for RF / IR attenuation

- Tints & frits

- High-definition printing

Optional Finishes - Frame and Glazing Stops

- Epoxy primed

- Epoxy primed and manufacturer’s standard powder coat (Contact Harden for color chart)

Optional Finishes - Interior/Exterior Trim

- Clear anodizing, 204-R1 or 215-R1

- Color anodizing

- Painted finish, AAMA 2604 (Contact Harden for color chart)

- Painted finish, AAMA 2605 (Contact Harden for color chart)

- Stainless steel cladding

Applicable Standards, Testing and Certifications

- UL 752: Standard for Bullet-Resisting Equipment

- NIJ 01.08.01: Ballistic-Resistant Protective Materials

- ASTM E283: Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen

- ASTM E331: Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference

- ASTM E330: Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference

- AAMA 501.1: Standard Test Method for Water Penetration of Windows, Curtain Walls and Doors Using Dynamic Pressure

- AAMA 501.5: Test Method for Thermal Cycling of Exterior Walls

- NFRC 100: Procedure for Determining Fenestration Product U-factors

- NFRC 200: Procedure for Determining Fenestration Product Solar Heat Gain Coefficient and Visible Transmittance at Normal Incidence

- NFRC 500: Procedure for Determining Fenestration Product Condensation Resistance Values

Installation Considerations

- Windows are fully glazed at the factory, and require only minimal preparation prior to installation

- Sub-frames can be shipped in advance of factory glazed window assembly

- Three different methods of installation into the structure, depending on the stage and type of wall construction:

- Pre-drilled and tapped plate-type embeds cast into concrete

- Pre-drilled and tapped steel tube-type sub-frames bolted into the wall

- Pre-drilled and tapped steel tube-type sub-frames welded to the wall structure

Maintenance

Regular inspection of window, trim and flashing is recommended.

Availability & Cost

Window systems are typically manufactured to order and subject to production lead times at the time of purchase.

Warranty

Harden warrants that its Architectural Security products shall remain free of defects in material and workmanship under normal use for a period determined by the individual project specification.

Most products and installations shown in the photos were completed under the previous ownership structure of Ross Technology Company. Building photos courtesy BL Harbert International or US Department of State. Harden maintains ownership rights of all product photos taken at Ross. For details on ownership of specific photos, please contact Harden Architectural Security Products directly.