Architectural Roof & Escape Hatches Maximum Security Hinged Access

Architectural Roof & Escape Hatches

Maximum Security Hinged Access

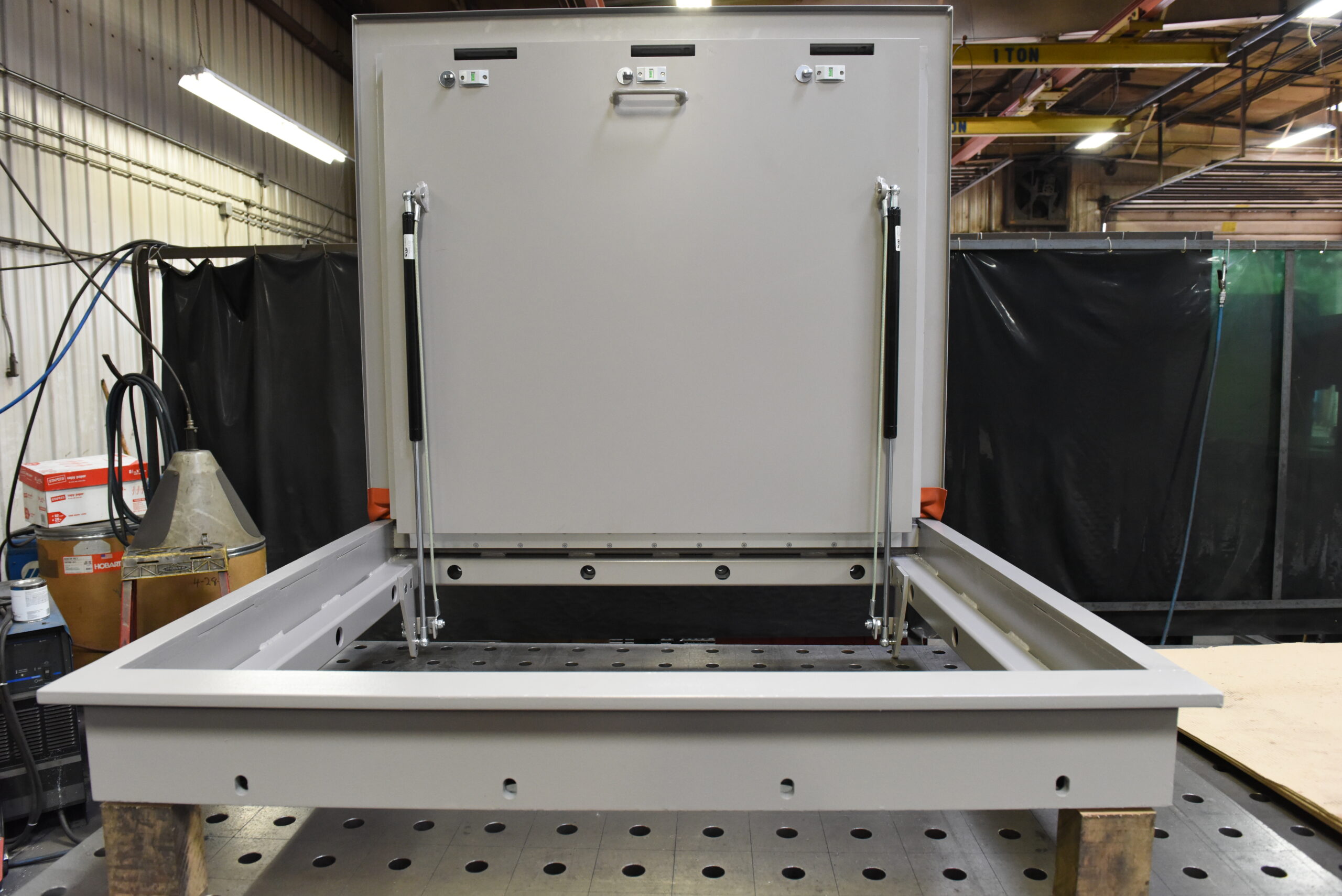

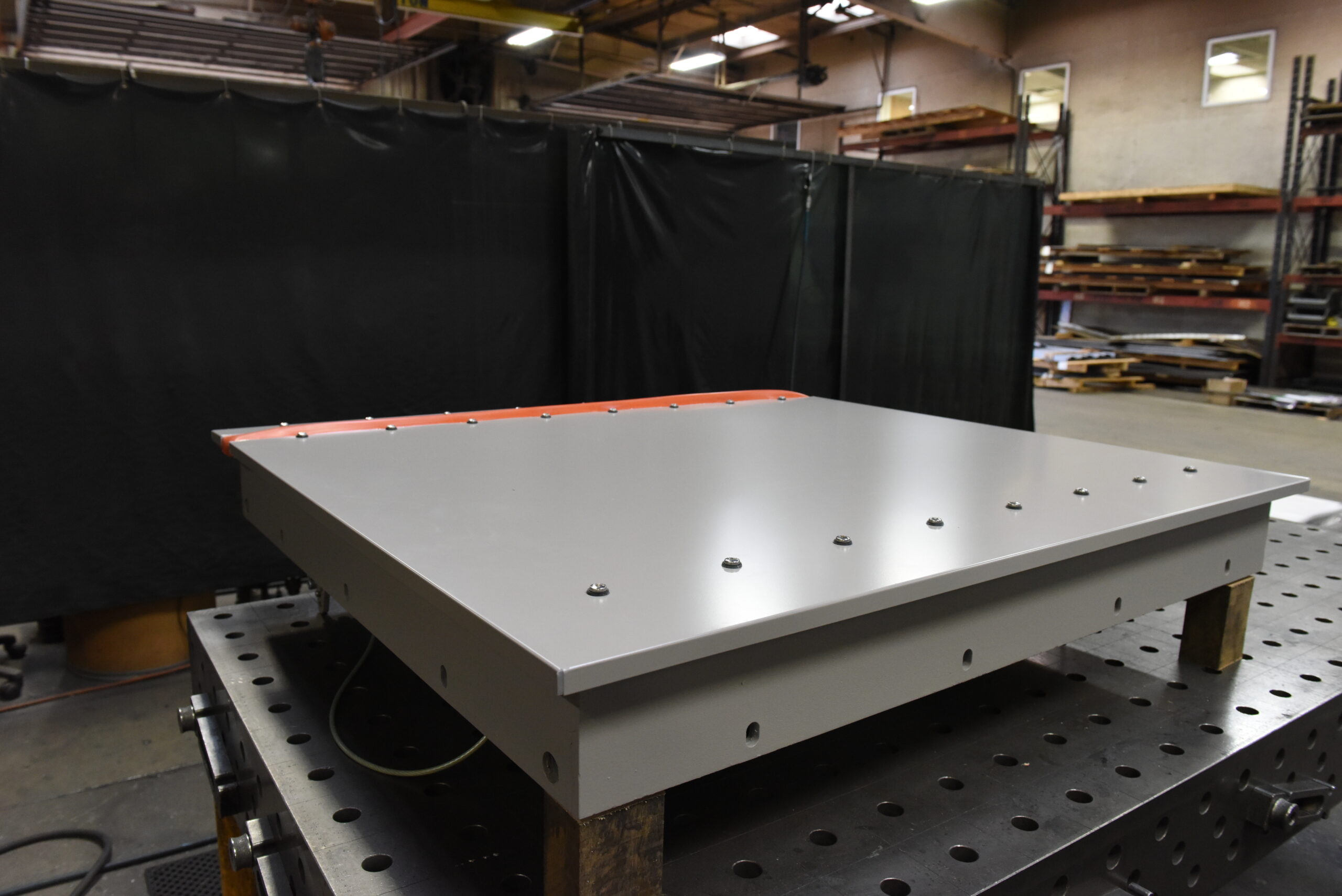

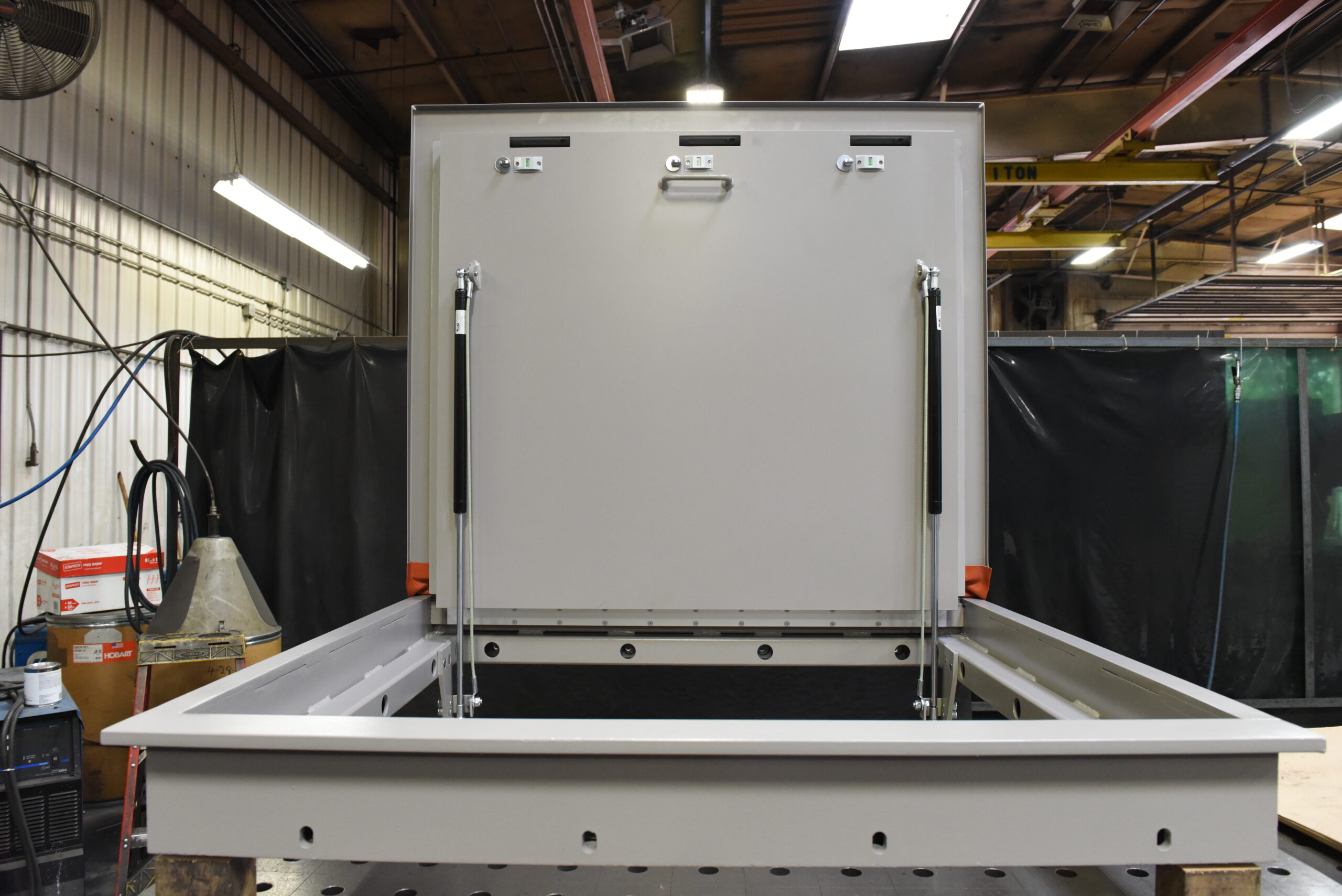

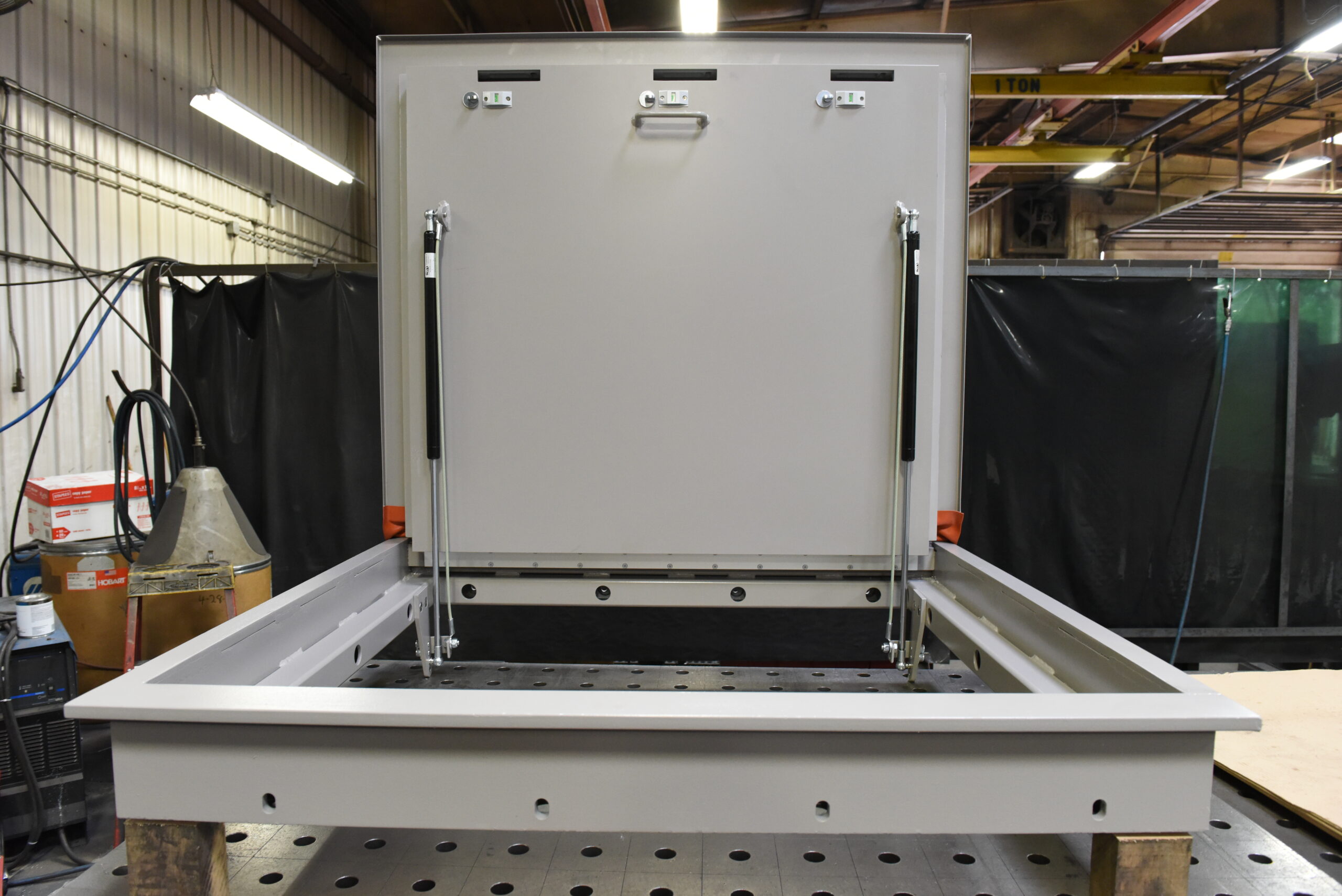

Certified to Department of State Standard SD-STD-01.01 Rev. G (Amended), Harden Maximum Security Hinged Hatches offer the utmost in DOS certified ballistic and forced-entry resistance for extreme threat conditions while providing a covert escape route for personnel. Designed to maximize the clear opening space within a given area, they offer the greatest amount of room for evacuating personnel and property. The hinged hatch is certified to withstand simulated forced-entry attacks for 60 minutes and 5.56 M193, 5.56 M855 and 7.62 M80 ballistic rounds. Fabricated as a complete system, typical construction includes a structural steel hatch frame with hinged panel and a plate or tube-type sub-frame.

Design Overview

ANTI-TERRORISM LEVEL SECURITY where conformance to U.S. Department of State forced-entry / ballistic resistant threat levels is required

EMERGENCY EGRESS where evacuation of personnel may become necessary

LARGE OPENING up to 42" x 36" clear opening accommodates most any access requirement

DESIGN FLEXIBILITY numerous finish options offer the ability to complement other building materials

DURABILITY structural steel materials and high-quality finishes provide extreme durability and low maintenance throughout the life cycle

Harden escape hatch designs have been used for many prominent and secure buildings. Maximum Security Hinged Hatches provide secure roof and floor level evacuation for prominent and mission critical buildings, safe rooms, control rooms, executive offices and anywhere the highest level of protection is important. Our customers include some of the largest government agencies, general contractors, integrators and corporations in the world.

- Government

- Military

- Oil & Gas

- Critical Infrastructure

- Commercial

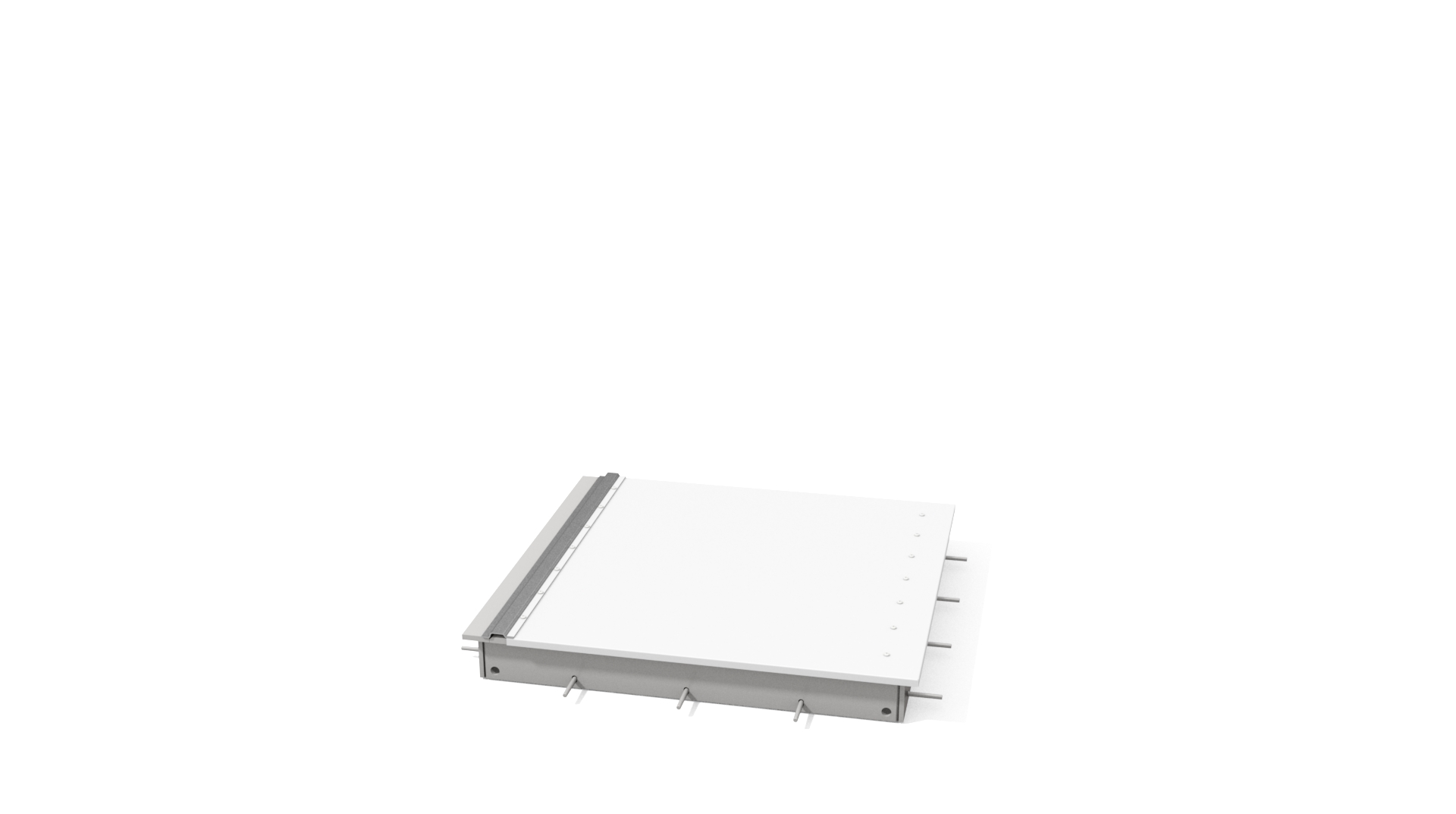

- Perimeter T-frame with hinged steel panel

- Pre-drilled and tapped sub-frame in one of three styles

- embed plate with studs for newly poured concrete walls

- tubing with chemical or mechanical anchors for existing masonry walls

- tubing for welding to steel walls

- Handle

- Gas strut assist

- Multiple locks, manually thrown

Standard Finish

- Epoxy primer

- Access ladder

- Weather cover

- Safety post

Optional Finish

- Epoxy primer with finish top coat. Contact Harden for color chart

Applicable Standards, Testing and Certifications

- Department of State, SD-STD-01.01 Rev. G (Amended): Certification Standard – Forced Entry and Ballistic Resistance of Structural Systems.

Installation Considerations

- Hatches are fully assembled at the factory, and require only minimal preparation prior to installation

- Sub-frames can be shipped in advance of hinged hatch assembly

- Three different methods of installation are available depending on the stage and type

of construction:

- Pre-drilled and tapped plate-type embeds cast into concrete

- Pre-drilled and tapped steel tube-type sub-frames bolted into the roof structure or curbing

- Pre-drilled and tapped steel tube-type sub-frames welded to the roof structure

Maintenance

Regular inspection of hatch operation, cover and flashing is recommended. See maintenance manual for details.

Availability & Cost

Hatches are typically manufactured to order and subject to production lead times at the time of purchase. Contact Harden for details.

Warranty

Harden warrants that its Architectural Security products shall remain free of defects in material and workmanship under normal use for a period determined by the individual project specification.

Most products and installations shown in the photos were completed under the previous ownership structure of Ross Technology Company. Building photos courtesy BL Harbert International or US Department of State. Harden maintains ownership rights of all product photos taken at Ross. For details on ownership of specific photos, please contact Harden Architectural Security Products directly.